Applications

Peening purpose: applicable for surface peening in automotive and aviation industry to optimize the fatigue performance of key safety components, for example: chassis , suspension ,gears in engine and gearbox ,power unit ,undercarriage , parts.

Cleaning purpose: shot cleaning, rust removing. For example: preparation for ship steel plate, forging and casting.

Executive standards

VDFI8001、SAE-J441、SAE –J827、SAE-J1993、SAE-AMS2431、SAE-AMS-S-13165

Size

| Comparison table | ||

| Grade | Size (mm) | Corresponding cast steel shot grade |

| CW12 | 0.30 | S-110 |

| CW14 | 0.35 | - |

| CW17 | 0.45 | - |

| CW20 | 0.50 | S-170 |

| CW23 | 0.60 | S-230 |

| CW28 | 0.70 | S-280 |

| CW32 | 0.80 | S-330 |

| CW35 | 0.90 | - |

| CW41 | 1.00 | S-390 |

| CW47 | 1.20 | S-460 |

| CW54 | 1.40 | S-550 |

| CW62 | 1.60 | S-660 |

| Other sizes can be customized upon request | ||

Hardness range

| Hardness range (HRC) | ||||

| Steel cut wire shot | 40-45 | 48-52 | 55-60 | 58-63 |

| Other specifications can be customized upon request | ||||

Types of shape

| Types of shape | |||

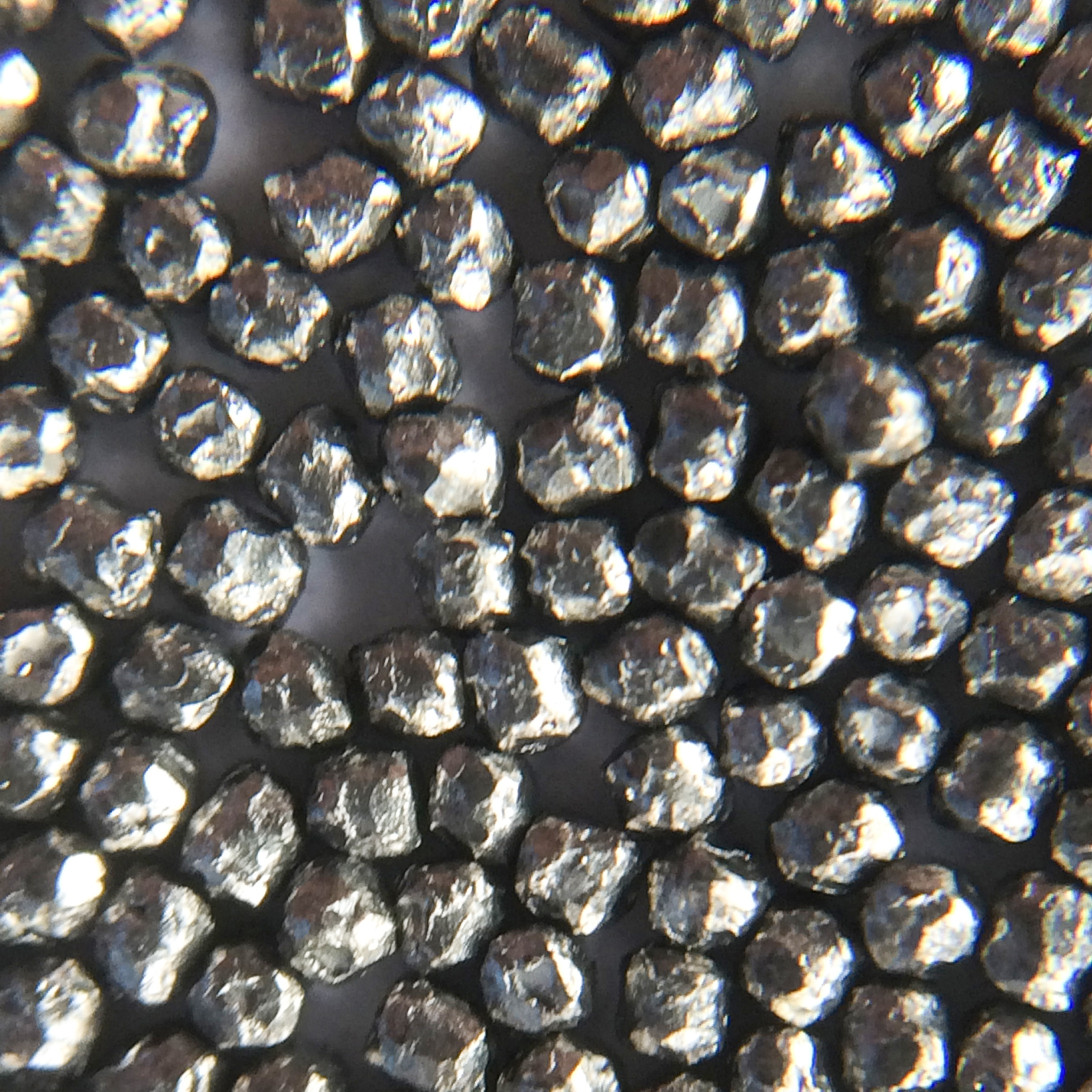

|

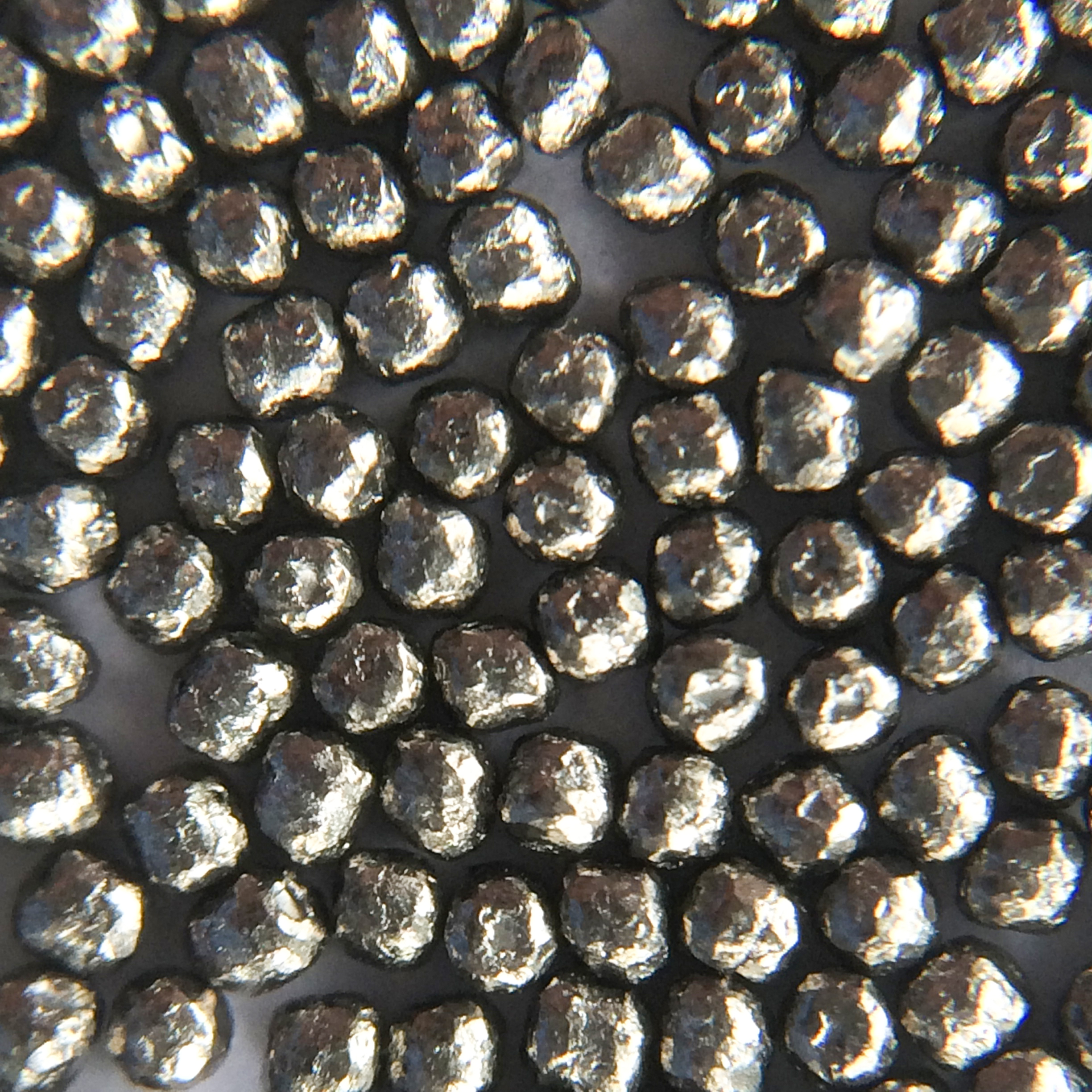

|

|

|

| As cut | G1 | G2 | G3 |